Recently Updated

Classification of Natural Granite:

Granite according to structural structure: can be divided into fine-grained granite, medium-grained granite, coarse-grained granite, porphyritic granite, plaque-like granite, crystal granite and granitic granite;

According to the sub-minerals contained in the granite, it can be divided into cassiterite-bearing granite, strontium-bearing iron ore, strontium-bearing granite, lithium mica granite, tourmaline granite, and the like. Common long-Petrochemical, Yunying lithification, electrical and petrochemical and other self-metamorphism.

The granite we often use includes granite, gneiss, gneiss granite, granitic schist and what the scholars call syenite and granodiorite. The usual granite is mainly composed of quartz, feldspar, marble and so on. Because of the presence of colored minerals, the overall color is affected by feldspar. The dark green or black rock of black granite is made of plagioclase, pyroxene, olivine, and hornblende. Therefore, black granite is divided into three types: porphyrite, diabase, and basalt.

Due to the well-balanced structure of the granite, the hardness is large, the color is bright, and the appearance is beautiful, which is a high-quality building material. Granite varieties and compressive strengths produced in different places are also different. Granite is not easy to be weathered due to its own quality. It can be kept for more than 100 years, and its structure and appearance are beautiful, it is architectural decoration engineering, ground material, open air. The preferred material for engraving.

2. Quality inspection requirements: The specified size or allowable deviation value is ≤±1mm, width and thickness ±1mm, surface flatness specified value or allowable deviation value ≤0.5mm, diagonal value or allowable deviation value ≤0.5mm .

3. Whether the appearance quality of the granite platform is superior, whether the color, color difference and pattern of the block are harmonious and uniform.

4. Whether there are defects such as ribs, corners, cracks, stains, color lines and pits on the surface of the platform.

5. Whether the surface of the platform is painted with six-sided stone protective coating to ensure the waterproof and anti-fouling performance of the stone.

6. Whether the stone has passed the relevant inspections of the National Stone Quality Monitoring Center, including physical, radioactive, freeze-thaw, etc., and has a test report.

7, stone origin and name.

According to the minerals contained in the granite: granite is divided into black granite, muscovite granite, hornblende granite, and two mica granite;

Granite according to structural structure: can be divided into fine-grained granite, medium-grained granite, coarse-grained granite, porphyritic granite, plaque-like granite, crystal granite and granitic granite;

According to the sub-minerals contained in the granite, it can be divided into cassiterite-bearing granite, strontium-bearing iron ore, strontium-bearing granite, lithium mica granite, tourmaline granite, and the like. Common long-Petrochemical, Yunying lithification, electrical and petrochemical and other self-metamorphism.

Natural Granite Features:

Granite is a granular structure with fine, medium or coarse grains, or a plaque-like structure. The particles are uniform and fine, the gap is small (the porosity is generally 0.3% to 0.7%), and the water absorption rate is not high (the water absorption rate is generally 0.15%). 0.46%), has good antifreeze properties. The hardness of granite is high, its Mohs hardness is about 6, and its density is between 2.63g/cm3 and 2.75g/cm3. Its compressive strength is 100-300MPa, and fine-grained granite can be as high as 300MPa or more. At 10 to 30 MPa. Granite is often produced in the form of rock foundations, rock strains, rock blocks, etc., and is controlled by regional geodetic structures. Generally, the scale is relatively large and the distribution is relatively wide. Therefore, it is easy to mine, easy to produce large materials, and its joint development is regular. It is conducive to the mining of stone with shape rules. Granite has a high rate of desertification and can be processed in various ways. Also, granite is not easily weathered and can be used as an outdoor decorative stone. Granite has a uniform texture and a light color, but it is also rich in red granite, white granite, yellow granite, green granite, black granite, purple granite, brown granite, beige granite, blue granite, etc. Its color change is relatively small, suitable for large-area use.

The granite we often use includes granite, gneiss, gneiss granite, granitic schist and what the scholars call syenite and granodiorite. The usual granite is mainly composed of quartz, feldspar, marble and so on. Because of the presence of colored minerals, the overall color is affected by feldspar. The dark green or black rock of black granite is made of plagioclase, pyroxene, olivine, and hornblende. Therefore, black granite is divided into three types: porphyrite, diabase, and basalt.

Due to the well-balanced structure of the granite, the hardness is large, the color is bright, and the appearance is beautiful, which is a high-quality building material. Granite varieties and compressive strengths produced in different places are also different. Granite is not easy to be weathered due to its own quality. It can be kept for more than 100 years, and its structure and appearance are beautiful, it is architectural decoration engineering, ground material, open air. The preferred material for engraving.

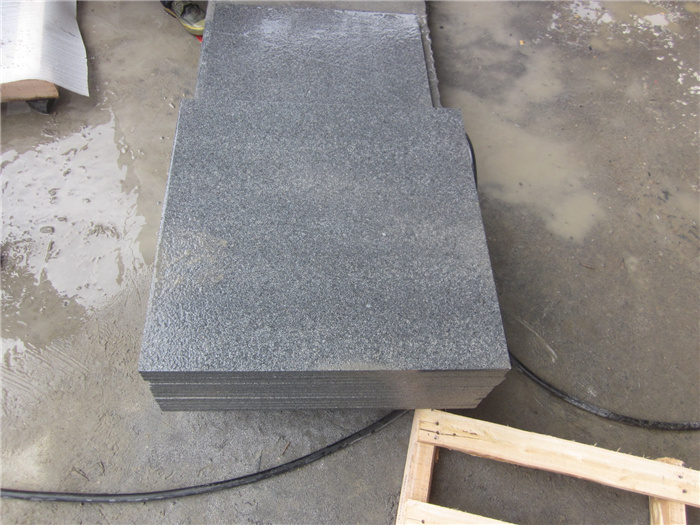

Natural Granite Processing Products:

According to the physical characteristics of natural granite can be used for processing into granite slabs, granite slabs, steps, countertops, window sills, floor slabs, mosaics, art sculptures, roadside stones, rolling stones, blind stones and special-shaped processing.

The Use of Granite is Based on Grain Size:

A: Fine grain can be polished or embossed as a decorative sheet or artwork;

B: Medium grain size is often used to build bridge piers, bridge arches, dams, seaports, feet, foundations, roads, etc.

C: coarse grain rolling into gravel, which is an excellent aggregate of concrete;

D: Because of the acid resistance of granite, it is also used as acid-resistant lining and container in chemical and metallurgical production.

Natural Granite Surface Processing Methods:

Granite is very practical and can be made into a variety of surfaces - polished surface, matt surface, fine grinding surface, fire surface, litchi surface, axe surface, blind board, water knife treatment and sandblasting surface.

How to Choose Natural Granite:

1. Check that the stone provided is natural stone, and whether its material properties meet or exceed natural granite (JB/T 7974-2001).

2. Quality inspection requirements: The specified size or allowable deviation value is ≤±1mm, width and thickness ±1mm, surface flatness specified value or allowable deviation value ≤0.5mm, diagonal value or allowable deviation value ≤0.5mm .

3. Whether the appearance quality of the granite platform is superior, whether the color, color difference and pattern of the block are harmonious and uniform.

4. Whether there are defects such as ribs, corners, cracks, stains, color lines and pits on the surface of the platform.

5. Whether the surface of the platform is painted with six-sided stone protective coating to ensure the waterproof and anti-fouling performance of the stone.

6. Whether the stone has passed the relevant inspections of the National Stone Quality Monitoring Center, including physical, radioactive, freeze-thaw, etc., and has a test report.

7, stone origin and name.